Electric welding machine (electric welding machine) is actually a transformer with lower external characteristics, which converts 220V and 380V alternating current into low-voltage direct current. Generally, electric welding machines can be divided into two types according to the output power source, one is AC power; the other is It is direct current. The direct current welding machine can be said to be a high-power rectifier. It is divided into positive and negative poles. When AC power is input, it is transformed by the transformer, and then rectified by the rectifier, and then output power with reduced external characteristics. The output terminal is on and off. When the two poles are short-circuited, the arc will be ignited, and the arc will be used to melt the welding rod and the welding material. After cooling, it will achieve the purpose of combining them.

The energy saving of the electric welding machine is embodied in two aspects: energy saving at no load and energy saving at load. The electric welding machine can stop the main circuit, fan, etc. at no load, and the no-load power consumption is only a few watts; the efficiency of the electric welding machine under load is higher than that of the thyristor rectifier welding machine.

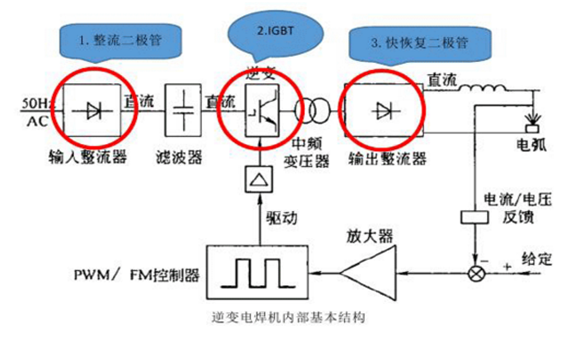

Here shows the electrical topology of the inverter welding machine. The hardware circuit is divided into: rectification, filtering, inverter, and rectification. The inverter parts is from YIXING IGBT:

Contact: Ashley Wu

Phone: +8616620962210

E-mail: ashley@yxmicrochips.com

Add: A840, 8th floor, Building A,Huayuan Science and Technology Innovation Park No 168 Bao Yuan Rd,Xixiang,Bao'an District, ShenZhen