The induction cooker, also known as the induction cooker, is a product of the modern kitchen revolution. It does not require an open flame or conduction heating and allows heat to be generated directly at the bottom of the pot, so the thermal efficiency has been greatly improved. It is a high-efficiency and energy-saving kitchenware, which is completely different from all traditional heat or non-fire conduction heating kitchenware. The induction cooker is an electric cooking appliance made by the principle of electromagnetic induction heating. It is composed of high-frequency induction heating coils (excitation coils), high-frequency power conversion devices, controllers, and ferromagnetic pot-bottom cooking utensils.

The induction cooker has two main components: one is the electronic circuit system (including the coil plate of the induction cooker) that can generate a high-frequency alternating magnetic field; Stove panel with rapid changes in heat and cold).

(1) The electronic circuit system includes: power board, main board, light board (control display board), temperature control, coil plate and thermal bracket, fan, power cord, etc.

(2) The structural shell includes: furnace panel (porcelain plate, black crystal plate), plastic upper and lower covers, etc.;

(3) Instruction, power sticker, operating film, certificate, plastic bag, shock-proof foam, packing box, barcode, cartoon box.

1. Furnace panel: used to carry pots and pans, imported and domestically produced, domestically produced A and B grades can meet the requirements of use.

2. High-voltage main substrate: constitutes the main current loop.

3. Low-voltage main substrate: used for computer control functions.

4. LED circuit board: display working status and transmit operating instructions.

5. Wire reel: convert high frequency alternating current into alternating magnetic field (PAN).

6. Fan assembly: heat dissipation auxiliary element (FAN), which reduces the temperature of the components in the furnace.

7. IGBT: commonly known as power tube, it controls the on-off of large current (IGBT) through low current signal.

8. Bridge rectifier block: convert AC power to DC power (BD101).

9. Thermistor: transfer the heat signal to the control circuit.

10. Thermal switch components: sense the working temperature of the IGBT to protect the IGBT from damage due to overheating.

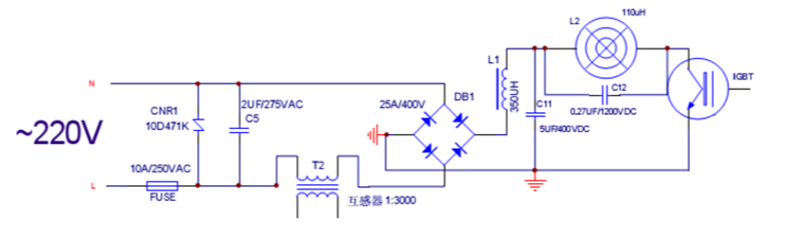

Here shows the electrical topology of the induction cooker. The hardware circuit is divided into three parts: rectification, switching, and electromagnetic heating. The switching parts is from YIXING IGBT:

Contact: Ashley Wu

Phone: +8616620962210

E-mail: ashley@yxmicrochips.com

Add: A840, 8th floor, Building A,Huayuan Science and Technology Innovation Park No 168 Bao Yuan Rd,Xixiang,Bao'an District, ShenZhen